PicoRaman M3 successfully employed in a study on application of PAT tools in perfusion cultures

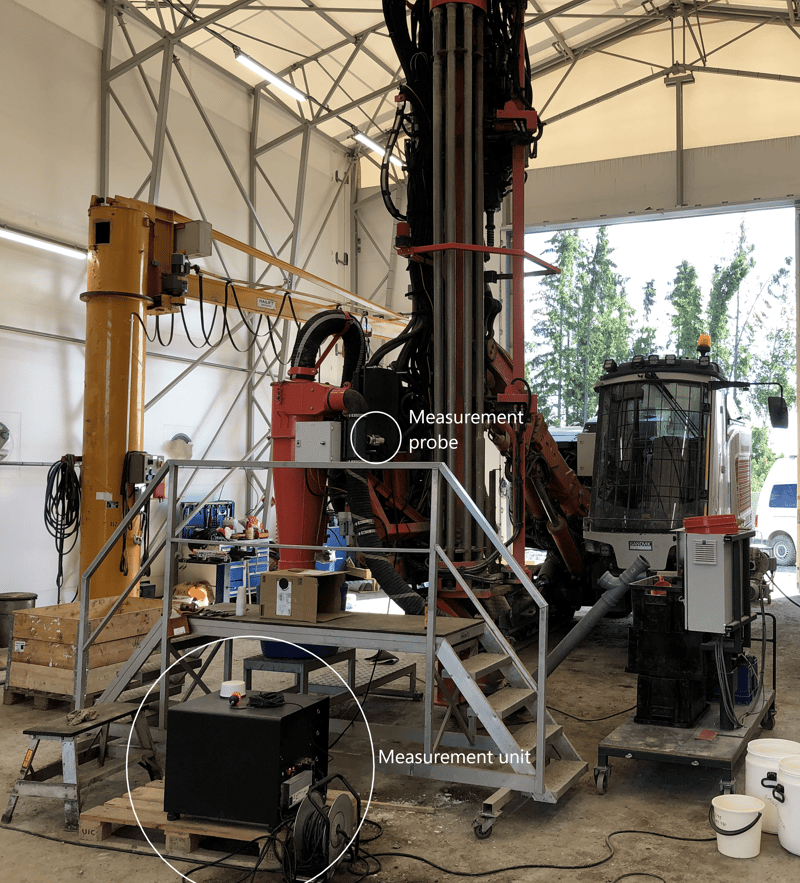

PicoRaman M3 was utilized in a study evaluating the application of time-gated Raman technology in perfusion cultures. Conducted by Fernanda Rebellato Giordano Martim of Kungliga Tekniska högskolan (KTH) as a Master's thesis, the study assessed the application of two Process Analytical Technologies (PAT) tools, with Timegated® Raman being one of them.

Main findings of the study regarding time-gated Raman included firstly the application of PAT tools, such as PicoRaman M3 in continuous manufacturing in the pharmaceutical industry. PAT tools enable automatic feedback control strategies to regulate the critical process parameters (CPPs) and product quality of bioprocesses. Additionally, the study found that Timegated® Raman data can be used to build predictive statistical models, thus enabling the real-time monitoring of key cultivation parameters. Furthermore, the researcher showed that high variability dataset produces more robust predictive models for enhancing reliability.

Learn more about the Timegated® tool by downloading the PicoRaman M3 brochure.

Abstract

Monoclonal antibody-based therapeutics (mAb) are one of the fastest-growing segments in the pharmaceutical market, mainly due to their application in oncology, immunology, and hematology. Traditionally, the industrial production of mAb is done with fed-batch cultivation. This is a relatively easy to operate process with mAb yields of 5-10 g/L, but its lack of control over critical process parameters (CPP) causes high mAb losses due to unmet quality specifications. Driven by increasing market demands and regulatory changes, the pharmaceutical industry is innovating in the mAb manufacturing process to reach continuous manufacturing. Currently, as a transition step to continuous manufacturing, the pharmaceutical industry is investing in intensified fed-batch cultivations. They achieve higher cells densities and present yields around 25-30 g/L, but this is still much lower than the equivalent mAb titers of 130 g/L that can be achieved with perfusion processes. Other advantages of perfusion processes are that they allow the existence of flexible production facilities, and enable a level of process control that would permit Real-Time Release Testing. To maintain a perfusion process under the specified conditions to guarantee the desired mAb quality, the CPP need to be closely controlled. Process Analytical Technologies (PAT) can measure CPP in real-time and non-destructively. This study evaluated the application of two PAT, the ArgusEye® sensors and Time-gated Raman spectroscopy, on perfusion processes. We showed that the ArgusEye® sensors can be used to measure IgG in perfusion samples with quite good correlation to the reference method. We have also shown that multivariate Raman-based models can be constructed to predict several CPP based on the same spectra. Most importantly, this study highlights the complexity of the application of these PAT to control perfusion processes. For the ArgusEye®, we conclude that to obtain accurate measurements, we need to account for the changes in the concentration of host cell protein during a perfusion process, as their unspecific binding to the sensors is the probable cause for the variation in the IgG measurements. For the Raman-based models, as previously reported in the literature, this study shows that a high volume of data is require to build accurate prediction models. Overall, this report shows that these PAT have a great potential of application, but they need to be further improved prior to their use as automatic feedback control tools.

Read more about the application of time-gated Raman technology in perfusion cultures from the Master's thesis.