Timegated® Technology solutions: real-time monitoring and bioprocess control

Solutions with Timegated® Raman Technology

Timegate focuses on building up Good Manufacturing Practice (GMP) compliance to help your company to deliver products that meet the highest global quality standards.

Focus to minimize the risks of variations in product quality, ensure consistency in manufacturing, and ultimately deliver safe and effective biopharmaceutical products to the market.

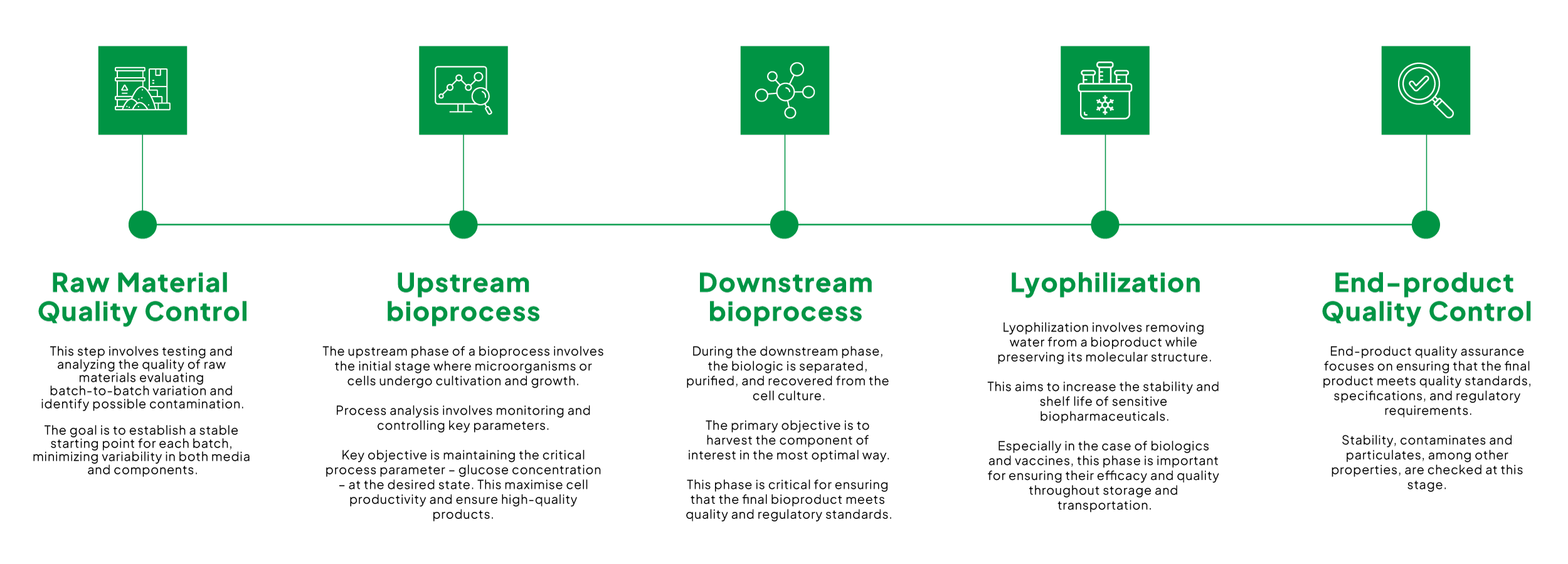

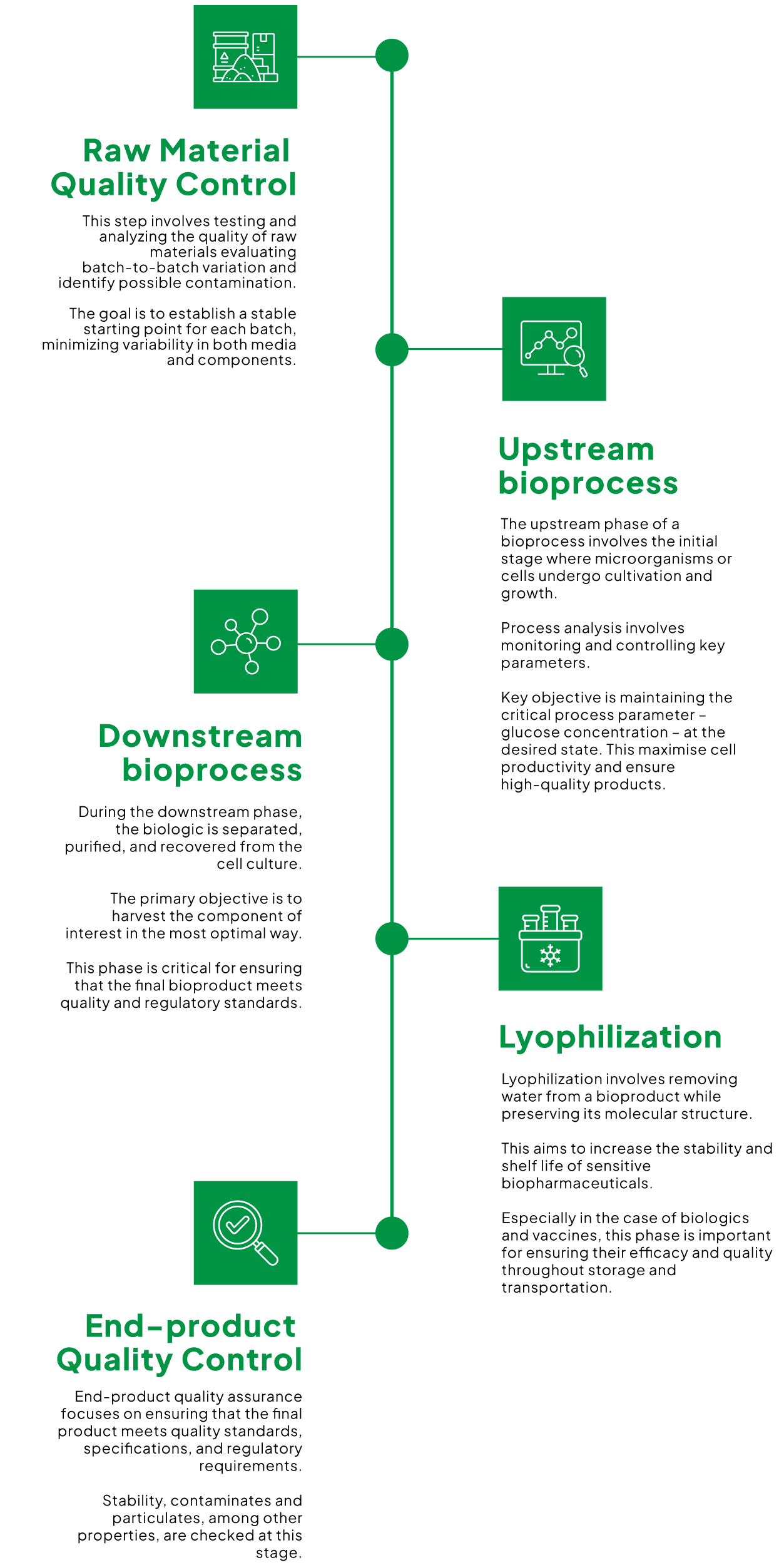

Raw Material Quality Control

Raw material quality control in biopharmaceutical processes is crucial for ensuring the safety and efficacy of the final product. Timegate provides process analytical tools and technologies for real-time monitoring and control from the beginning throughout the entire biopharmaceutical manufacturing process.

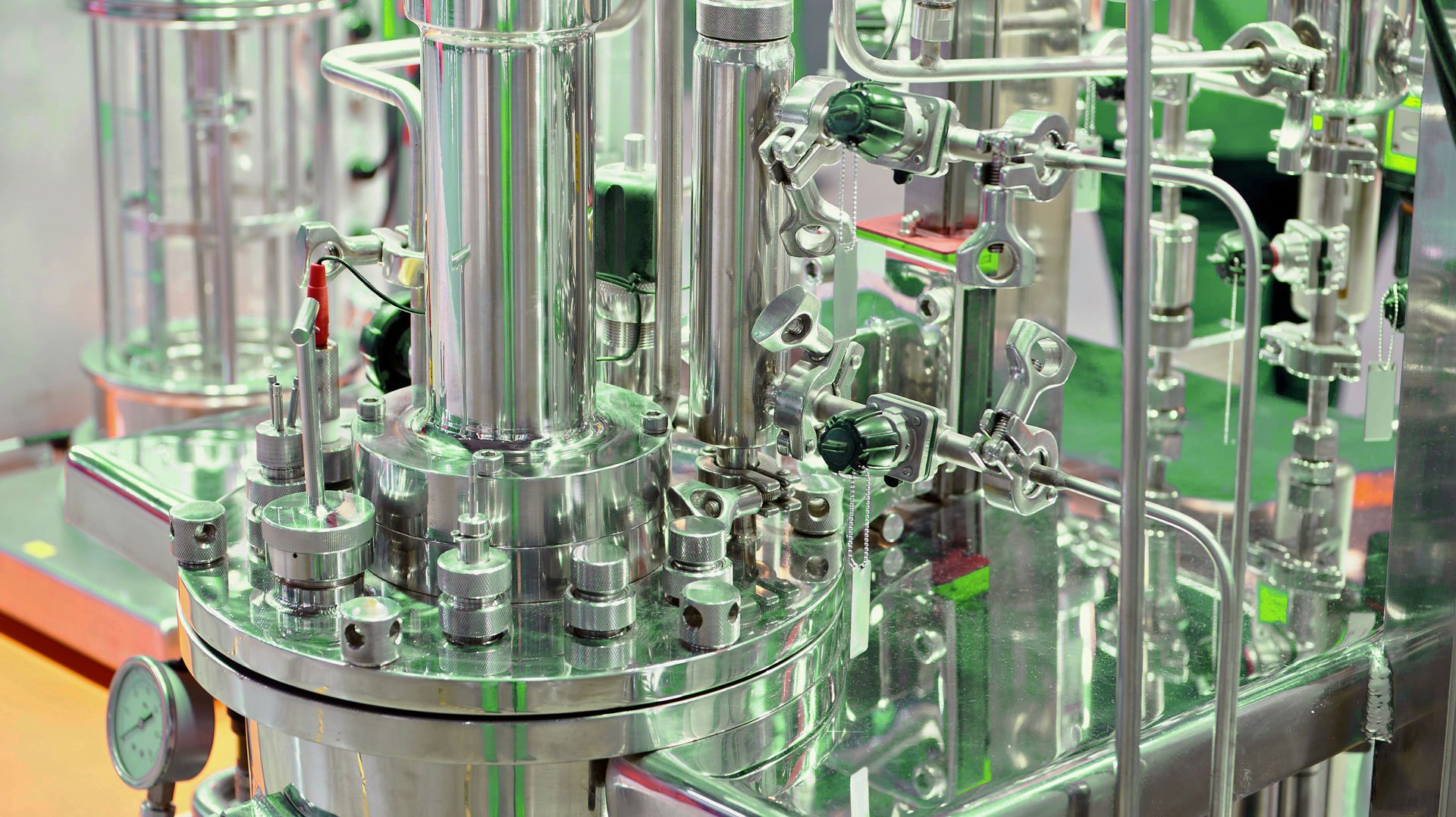

Upstream Bioprocess

Are you struggling to keep the nutrient levels within the desired limits in the bioreactor? Optimizing the upstream process is crucial for achieving high yields and maintaining product quality in biopharmaceutical manufacturing. We have a solution for this.

Downstream Bioprocess

Optimizing the downstream process is pivotal in achieving a high purity bioproduct with consistent quality. With Timegated® Raman Technology isolation of the desired protein is optimized leading to increased yield.

Monitoring Lyophilization Process

How to make sure that the polymorphic structure of the bioproduct remains unchanged during the lyophilization process? Timegated® Raman technology provides a unique molecular fingerprint, and shows if the molecular structure remains the same.

End-product Quality Control

Timegated® technology enhances bioprocess efficacy for improved end-product quality and safety with real-time process analytics. Timegate provides fast and accurate data through automated measurements of 96 samples simultaneously.